First, a wall is made: Either with oil based clay or a paper cup cut to size and hot-glued to a board.

Next, the silicone is mixed:

The High Temp Silicone we use is mixed in a 10:1 ratio.

10 parts silicone to 1 part catalyst.

(So if you're using 80 ML of silicone, you'd mix in 8 ml of catalyst.)

Students are to make a mold for a small object so we can cast it in resin or in Metal.

Evaluation:

2 points -- Mold walls made correctly

1 point -- Silicone mixed and poured correctly

2 points -- Minimal bubbles in the mold

3 points -- Mold cut and deflashed properly

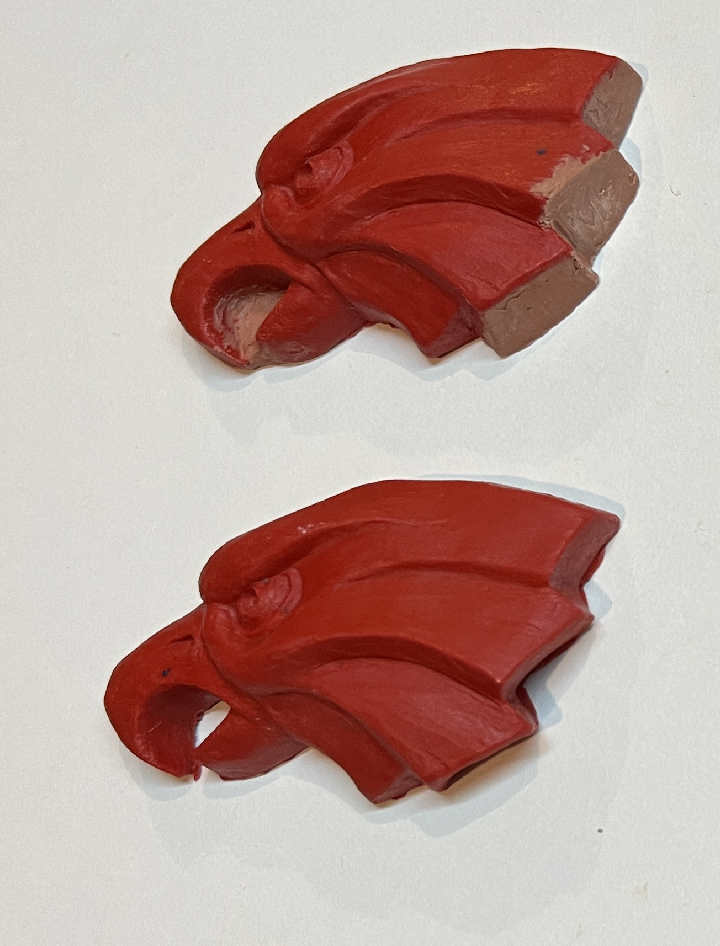

2 points -- 2 casts made (metal or resin)

10 points total

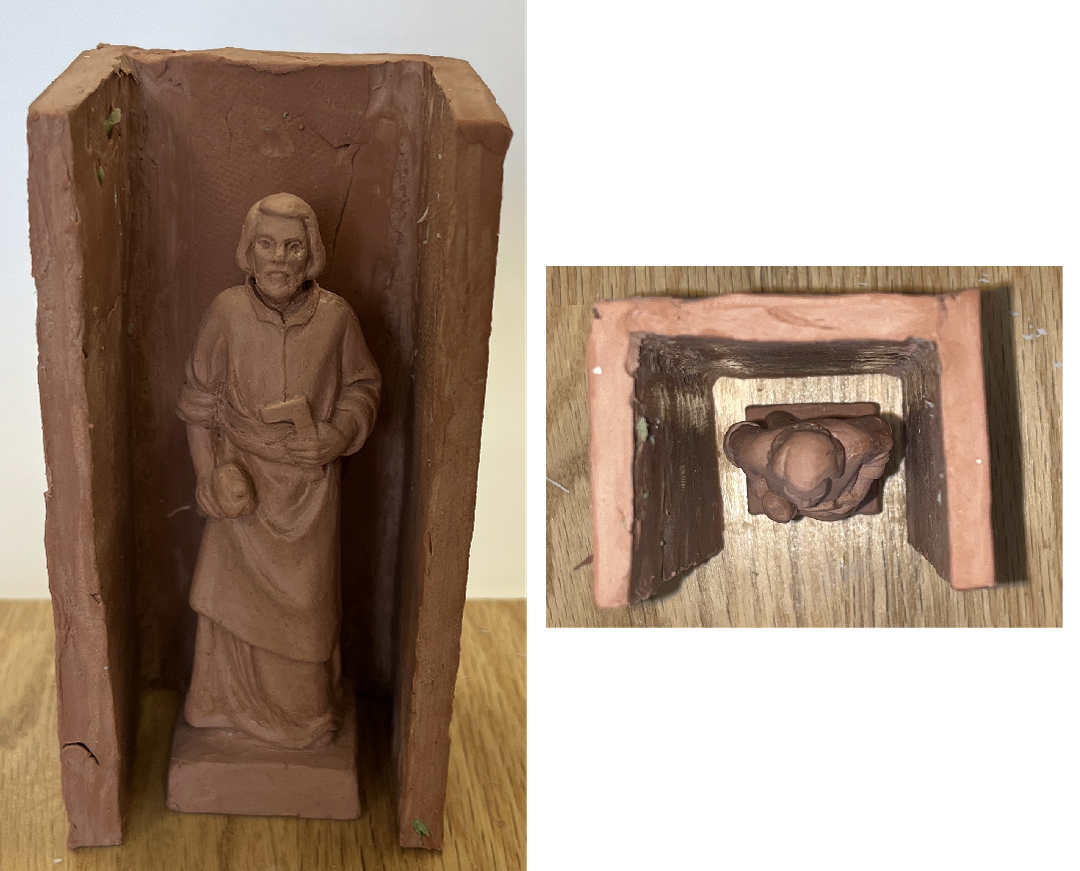

Sometimes clay may need to be added to make the piece more easily castable. Below clay has been added to the piece to avoid undercuts.

Wall up the piece with sufficient space around it.

Reinforcing tape has been added to avoid leaks and blowouts as silicone is poured into the mold. Also note the front is labeled to ensure the seam isn't cut along an important face.

Wall up the piece with sufficient space around it.

Reinforcing tape has been added to avoid leaks and blowouts as silicone is poured into the mold. Also note the front is labeled to ensure the seam isn't cut along an important face.