First, a wall is made: Either with oil based clay or a paper cup cut to size and hot-glued to a board.

Next, the silicone is mixed:

The High Temp Silicone we use is mixed in a 10:1 ratio.

10 parts silicone to 1 part catalyst.

(So if you're using 80 ML of silicone, you'd mix in 8 ml of catalyst.)

Students are to make a mold for their Oil-clay project so we can cast it in resin and in Metal.

Evaluation:

2 points -- Mold walls made correctly

3 points -- Silicone mixed and poured correctly

2 points -- Minimal bubbles in the mold

3 points -- Mold cleaned up and deflashed properly

10 points total

Illustration 1 below is the original piece made with Chavant clay.

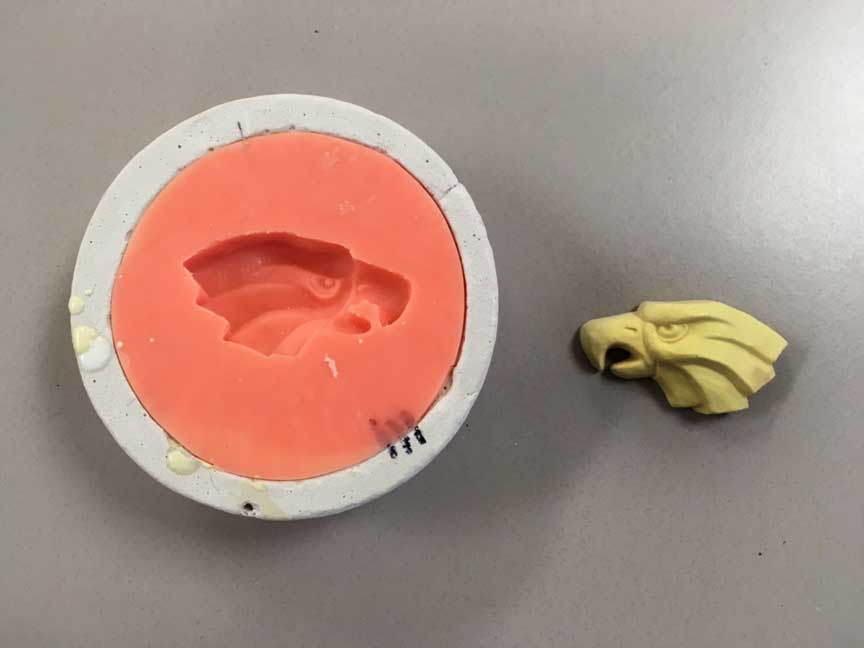

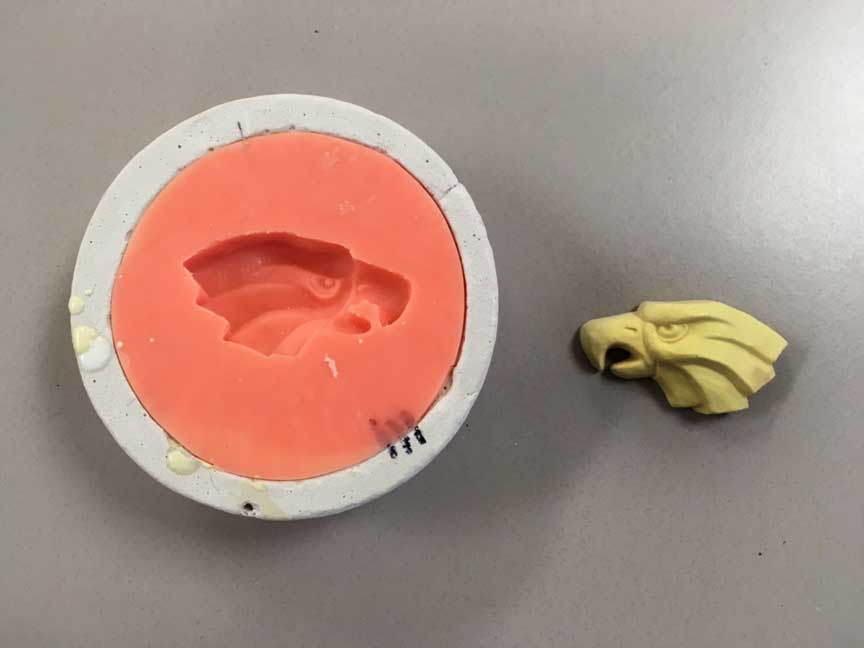

Illustration 2 below shows the silicone mold and plaster mother-mold with the finished cast piece.

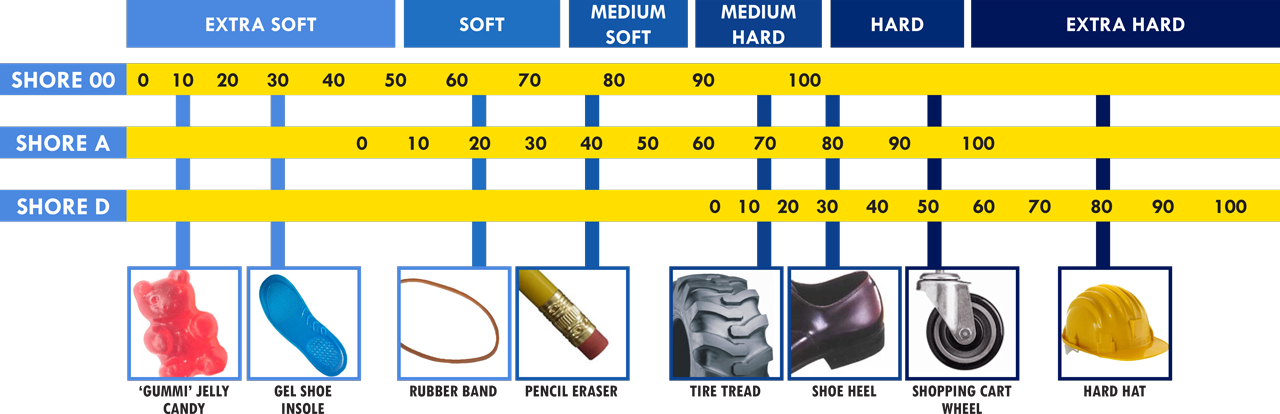

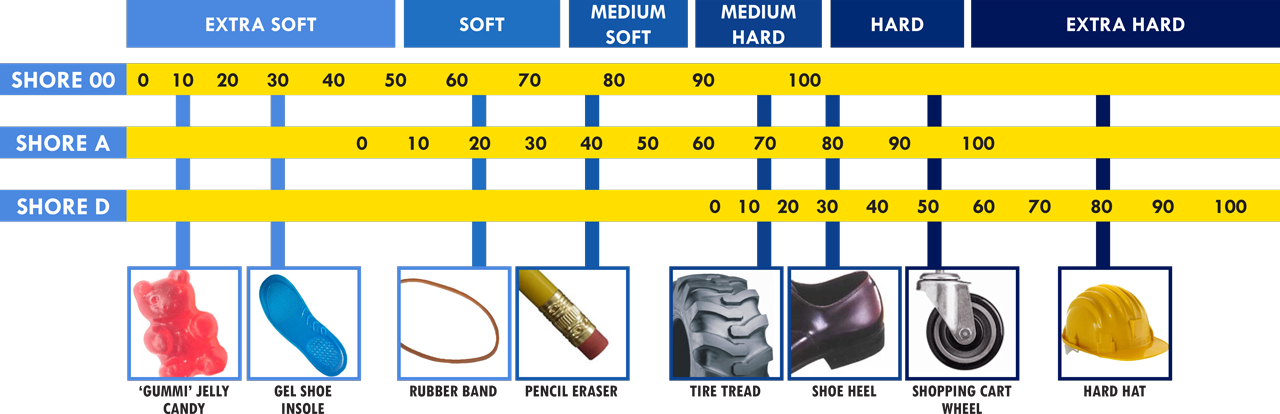

Below is a Durometer chart. Our silicone is a High Temp., high durometer RTV silicone. Ours falls between 40 and 60 on the Shore A scale.

Illustration 2 below shows the silicone mold and plaster mother-mold with the finished cast piece.

Below is a Durometer chart. Our silicone is a High Temp., high durometer RTV silicone. Ours falls between 40 and 60 on the Shore A scale.